How to Reduce the Formation of Solder Balls-Solder Paste Selection

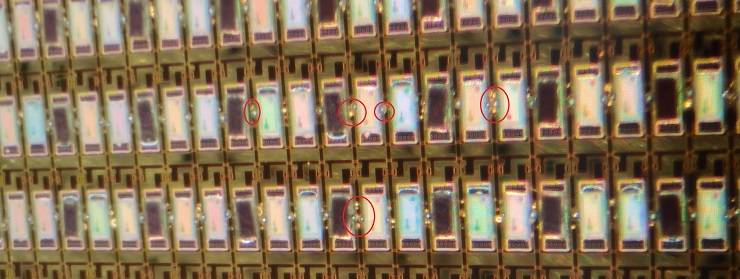

1. The hazards of solder balls

There are solder balls with sizes about 0.2mm~0.4mm, or some exceed this range, which is mostly concentrated around chip RC components. The existence of solder balls not only affects the appearance of electronic products but also brings hidden dangers to product quality. Due to the high density and fine pitch of modern printed circuit board components, the solder balls are easy to lift off when using, resulting in short circuits and affecting the quality of electronic products. Therefore, it is very important to understand the causes and control of solder balls.

2. The reason why solder paste turns to solder balls

Generally speaking, there are many reasons for the generation of solder balls, such as the thickness of the printing solder paste, the composition and oxidation of the solder paste, the production and aperture of the stencil, the water absorption of the solder paste, the mounting pressure of the components, the soldering performance of the components and the pads, the setting of the reflow soldering temperature, and the influence of the external environment.

So what are the causes and solutions of solder balls?

The choice of solder paste directly affects the soldering quality. Factors such as the metal content, the oxygen content, the particle size of the solder alloy, and the thickness of the solder paste printing will lead to solder balls.

2.1 Usually, the mass percentage of metal alloy in solder paste products is 88%~92%, and the volume ratio of solder paste is about 50%. As the metal content increases, the viscosity of the solder paste increases, which can effectively suppress the stress generated by evaporation during preheating. In addition, the increased metal content allows the metal powder to aggregate when melted. Moreover, the increase in metal content reduces the possibility of the slump of the solder paste after printing, which makes it less prone to solder ball generation.

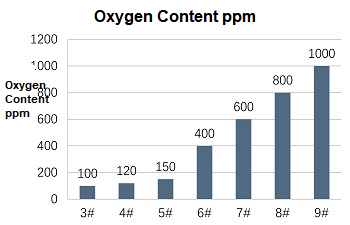

2.2 Generally speaking, the higher the oxygen content of the solder paste, the greater the bonding resistance during soldering, the less wettability between the solder paste and the pads, and the worse the solderability. The test results show that the generation rate of solder balls is proportional to the degree of oxidation of the metal powder. Hence, the general oxygen content and maximum oxygen content of solder paste should not be higher than 0.05% and 0.15%, respectively.

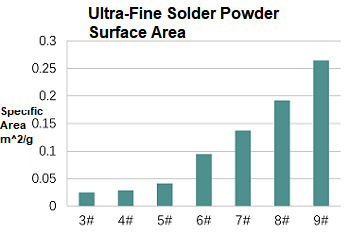

2.3 The small size of the solder paste alloy causes a large total surface area, which leads to an increase in the degree of oxidation of the finer powder and aggravates the phenomenon of the solder ball. The test results show that solder paste with small particle sizes is more likely to produce solder balls.

Fitech’s ultra-fine solder alloy powder size and oxygen content

As the particle size of the solder paste decreases, the specific surface area increases sharply. The oxygen content of solder paste controlled within a reasonable range effectively reduces the probability of solder ball formation.

2.4 The thickness of solder paste is an important parameter of printing, which should be controlled within the range of 0.12-20mm. Excessively thick solder paste will cause slumps and solder balls.

2.5 If the amount of flux is too large, the solder paste is more likely to slump locally, resulting in the formation of solder balls. In addition, when the flux activity is small, the deoxidizing ability of the flux is weak, which can lead to solder ball generation. No-clean solder pastes are less active than rosin and water-soluble solder pastes. Therefore, it is more likely to form solder balls.

What’s more, the solder paste should be refrigerated when the work plan is paused. It should be rewarmed to room temperature before reuse. Otherwise, the solder paste will easily absorb water, increasing the probability of splashing and solder ball formation.