Ethiopian student visits GMCC, the world's largest compressor manufacturer: provides the 'heart' for half of the world's air conditioners, assembling a compressor in 6s

As global summer temperatures reach record highs in recent years, air conditioners have become essential to daily life. A key component in every air conditioner is the compressor, and what many may not know is that one out of every two air conditioners in the world uses a compressor produced by a company based in Guangdong, China—GMCC.

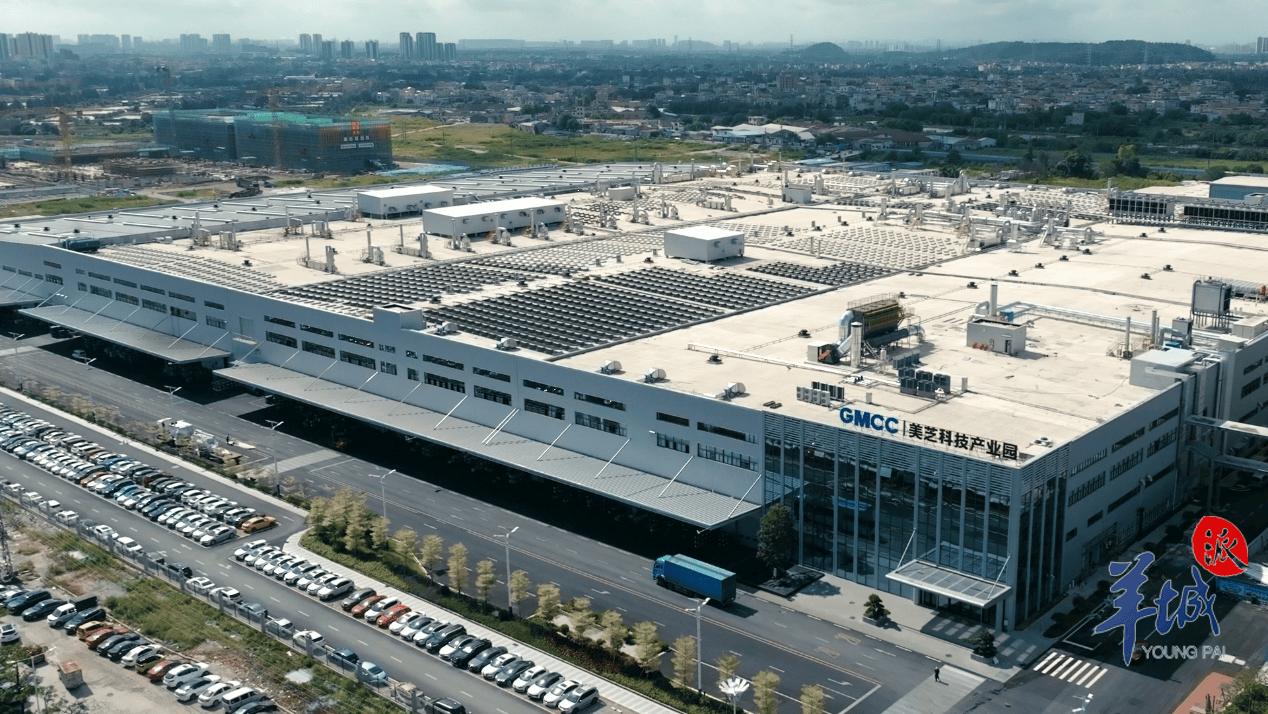

Recently, Yonatan, an Ethiopian student at Guangdong University of Foreign Studies, visited the world's largest air conditioning compressor manufacturing base, GMCC Meizhi Science and Technology Park in Shunde, Foshan. During the visit, he had the opportunity to explore the intelligent production workshop and experience firsthand the innovation behind "Intelligent manufacturing in Guangdong."

In the factory's first-floor exhibition hall, Yonatan noticed a slogan on the wall: "One out of every two air conditioners worldwide uses a GMCC compressor." Curiously, he asked, "Is this true?" Zhang Hewen, the manager at the GMCC Meizhi Science and Technology Park, confirmed, "Yes, that's correct! In 2006, GMCC ranked number one in the global market, and by 2021, annual sales had exceeded 100 million units. As of 2023, GMCC holds a 45% share of the global air conditioning compressor market."

As Yonatan toured the factory, he observed fewer workers than expected on the production line, with most of the work being handled by robotic arms, complemented by human operators. Zhang explained that the Park, recently put into operation, has achieved a 65% automation rate, with 1,000 robots for every 10,000 employees—a ratio of one robot per 10 workers.

Yonatan asked, "How long does it take to produce one compressor in such an automated factory?" Zhang responded, "Each compressor requires multiple components, with varying production times. On average, some parts take as little as three seconds, while others take longer. We can produce a finished compressor on our main assembly line in just six seconds." Notably, GMCC's one billionth compressor rolled off the production line in September of this year.

Source : Lingnan on the Cloud

埃塞俄比亚留学生探访世界最大压缩机企业:

总装线6秒下线一台压缩机,为全球一半的空调造“心”

近年来,地球夏季气温屡创新高,空调已经成为人们的生活必需品。而要想制造一台空调,压缩机是不可或缺的核心部件。或许很多人不知道的是,世界上每两台空调,就有一台使用这家广东企业生产的压缩机。这家企业就是来自广东的美芝(GMCC)。

近日,来自广东外语外贸大学的埃塞俄比亚留学生Yonatan(中文名王子,以下的王子均可翻译为Yonatan)探访了世界上最大的空调压缩机制造基地,位于佛山顺德的美芝科技产业园(美芝杏坛工厂),实地参观智能化的生产车间,亲身感受了什么是“广东智造”。

工厂一楼的展厅内,王子留意到展厅墙上“全球每两台空调,就有一台使用美芝压缩机”的标语,不禁发问:“这是真的吗?”美芝科技产业园管理负责人张贺文告诉他:“没错!2006年美芝在全球市场占有率就达到了第一,2021年年销售超过1亿台。2023年美芝的空调压缩机全球市场占有率达到了45%。”

走进工厂,王子发现工厂内工人数量并不如他想象的那么多,生产线上大多数都是机械臂在工作,工人辅以配合操作。张贺文向王子介绍,美芝科技产业园刚刚投产不久,目前自动化水平已达到 65%,万人机器人保有量达到 1000,也就是说,每10个工人配备一台机器人。

“在这样的智能化工厂里,生产一台压缩机需要多久?”王子又提出一个疑问。张贺文介绍,“一台压缩机需要多个配件,这些配件的生产时间不等,平均下来有3秒的,也可能时间更长。在总装的生产线上,我们能够实现6秒钟就能够下线一台压缩机。”值得一提的是,就在今年9月,美芝生产的第十亿台压缩机下线。

总策划丨杜传贵、林海利

总统筹|胡泉、蒋铮

执行统筹|赵鹏、李国辉

文、图|付怡 温泽广

视频剪辑丨温泽广

鸣谢丨广东外语外贸大学留学生教育学院

翻译丨邹晓华

英文审校丨林佳岱